Factories

Our PPE Glove factory

Sialkot

During 2015 we bought land and build our own production unit tailor made to our market needs.

The unit is in a new industrial area on high ground and next to main road connections. Initially the unit have 3 floors where we employ close to 1000 workers. We have made the foundation strong thus can add an additional 3 floors. Further we still have about 70% of the land available where we plan to add a additional production unit during 2025. On current land we expect to have room for about 5000 workers. A big part of our power supply comes from our own solar cell rooftop, thus we are less affected by energy shortage and rising energy prices. All cutting is done on hydraulic machines. We have in-house designers and TPR tooling and fully automatic TPR and decorative design sticking machines. Once a customer have chosen a design, it will stay with that customer only.

Unlike other glove manufacturers in Pakistan, we have chain systems with full time-employed workers. This means as qty. goes up stitching will become more even, since one worker is only making one seam and not a whole glove. Thus, we will not phase any quality problems in big orders, on the contraire it will become better.

We have a vast knowledge in adding functional properties into our materials and leathers thus our main customers are today serving Oil & Gas, Fire Fighters, Heavy Industry, Police & Military.

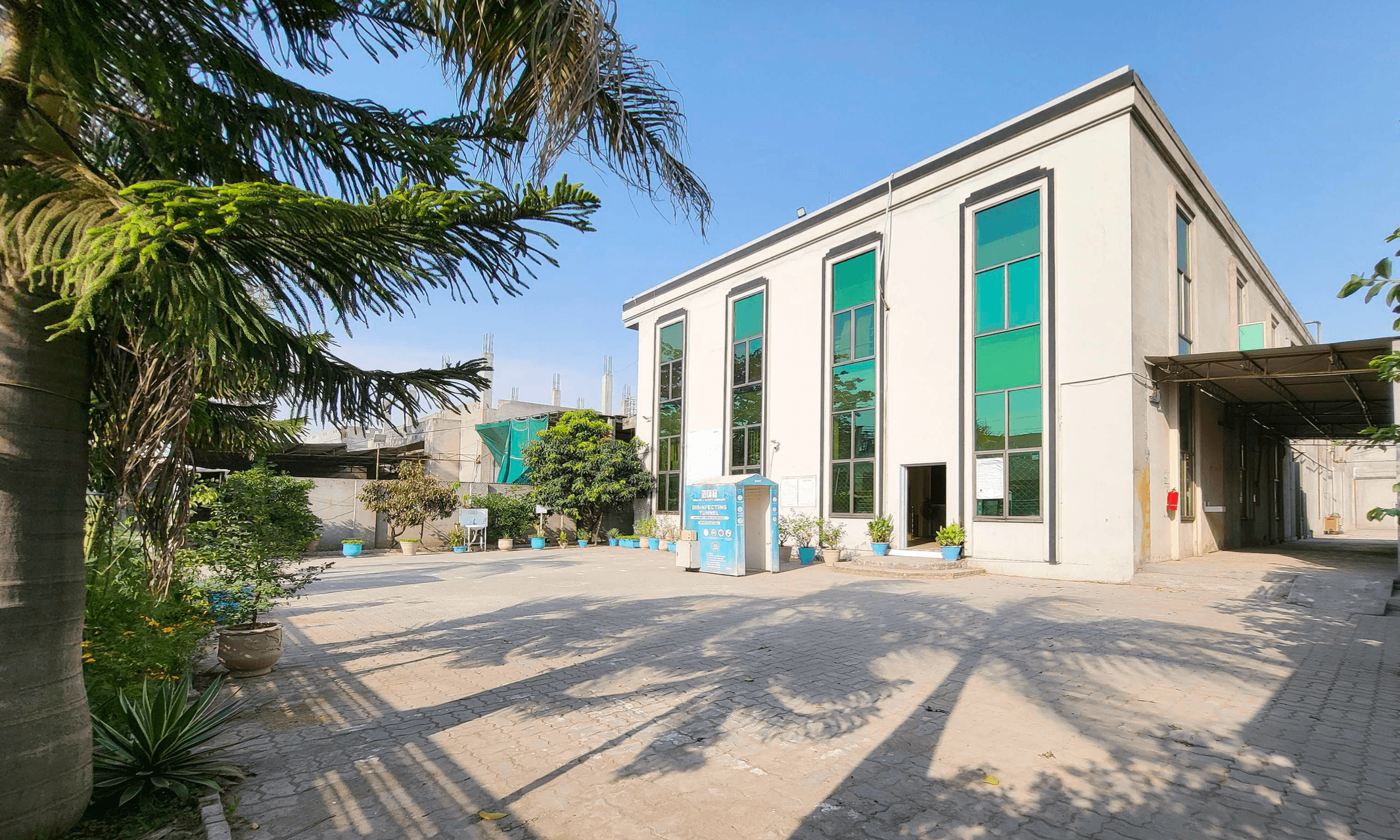

Our PPE & Fashion Garment factory

Sialkot

In 2015 we bought and moved into a new factory building initially with space for 300 workers and with available land to further expand the unit to 500 workers.

We produce outerwear, unconstructed blazers, shirts, skirts, dresses, shorts and trousers in leather, synthetics, wool, cotton and cut resistant knits for fashion and work wear markets.

We are very proactive in developing new materials and trims. We have a collection of approx. 1000 panels incl. goat, sheep, cow and buffalo leathers, shearlings, furs, wool, cotton and synthetics with cut, heat, arc, F/R, & puncture resistant properties materials.

We have a large collection of trims ex. braiding, embossing, perforation, patchwork, laser cutting, quilting and decorative seam work by hand or machine. We do very technical & good quality embroidery work, 2 & 3D digital print on leather, lining and textiles and deep embossing using special Japanese machines, all from small to large sizes.

We have given all materials price indexes. All leathers have price indexes in up to 4 grades from A/B to C/D grade. The price indexes enable our customers to make their own fast and easy price estimation of any garment in any materials we have send to our customers.

Our customers normally select and keep a collection of materials from us each time we meet, in order to use these material collections when designing and deciding on future collections.

Certifications & Compliances

Legally all PPE product sold in Europe, North America and Australia must be tested and certified by notified bodies according to EN standards for Europe and ANSI standards for North America.

We therefore often have inspections by certified auditors and for some PPE customers also during and after each production lot.

Being a part of an innovative PPE supplier ensures that our compliances are of the highest level.

We have implemented SOP’s that can continuously secure that our materials will comply with Reach & Prop 65. Our tannery partners are all LWG certified and certifications can be forwarded. We were Amazon audited for quality and CSR in 2019 and we implemented Lean System in 2023. Below our SA8000, ISO9001 and BSCI certifications: